Worldwide shipping 4.65/5 out of 2.300+ reviews

Rifle Scopes

Mounts

All Categories

Sport Optics

Hunting

Shooting

Reloading

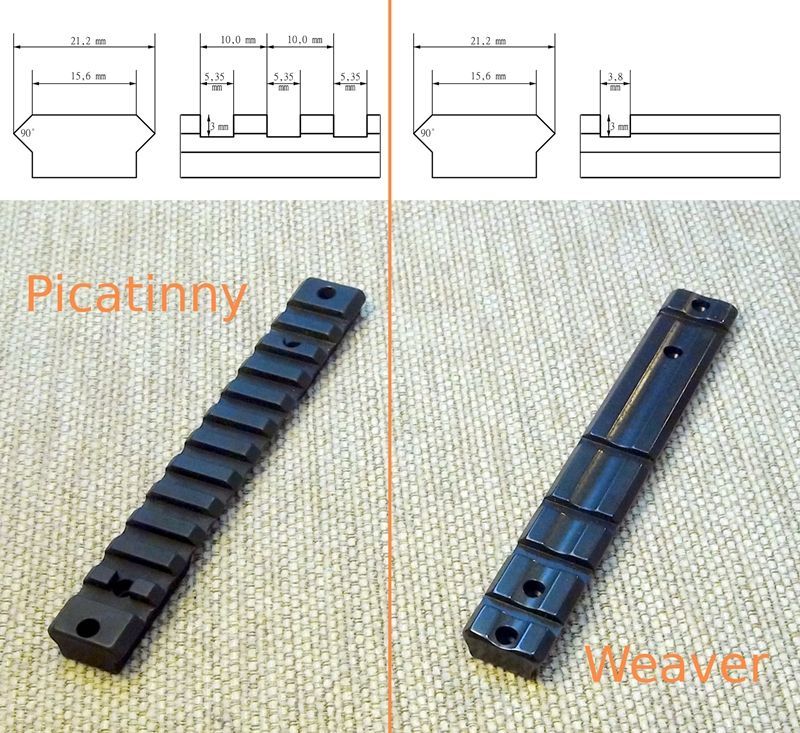

Scope Mounts